Company

Since its foundation 150 years ago, CAS Aufermann has been committed to the highest possible quality standards for both its own products as well as for contract work.

Our Company since 1869

CAS Aufermann’s head office has been located in Lüdenscheid since the company was founded in 1869. Approximately 25 employees work here.The main focus at all times is on the quality of the products: certified according to EN ISO 9001:2015.

Company

History since 1869

It all started with wooden handles

1869

Trained as a wood turner Carl Aufermann founded today’s company at the age of 42 with the production of wooden handles – these are wooden handles for files and other tools. Trouser and waistcoat buckles as well as trouser hooks and eyelets were in great demand at this time. Although C. Aufermann was a trained woodworker, he also had the skill to work with other materials and started to make other items by hand. It soon became clear that this was the right step towards a viable future.

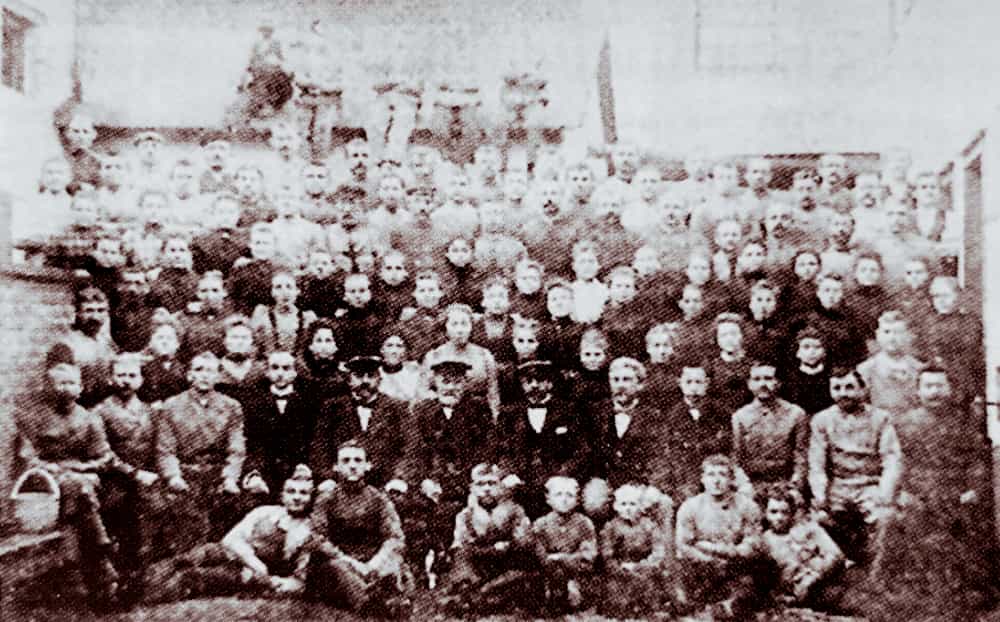

Strong demand for metal goods

1874

The demand for these “New items” was soon so great that employees had to be hired. The first move to a more central location took place after just five years to improve transport connections, and soon over 40 people were employed there.

“C. Aufermann + Söhne”

1880

New partners joined the company who were later replaced by their sons. This led to the name of the company, which is still used as the official name of the company today:

C. Aufermann + Söhne

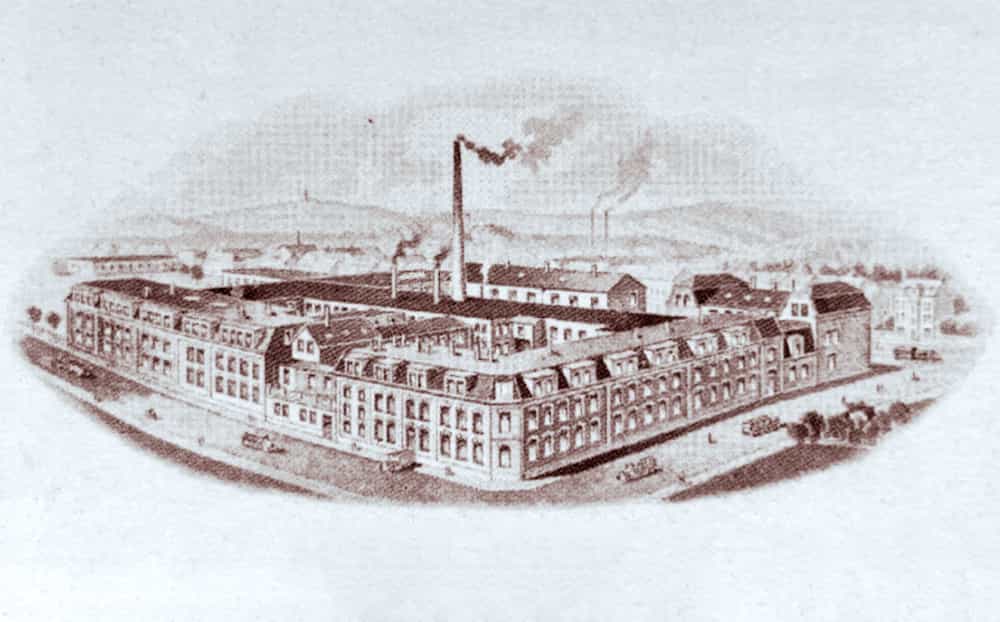

270 Employees for clothing accessories

1902

At that time, the product portfolio included trouser brace buckles, stocking and sock-holder sets, garters, and belt clasps. At the outbreak of the First World War in 1914, 230 people were employed at the company location and 40 worked from home.

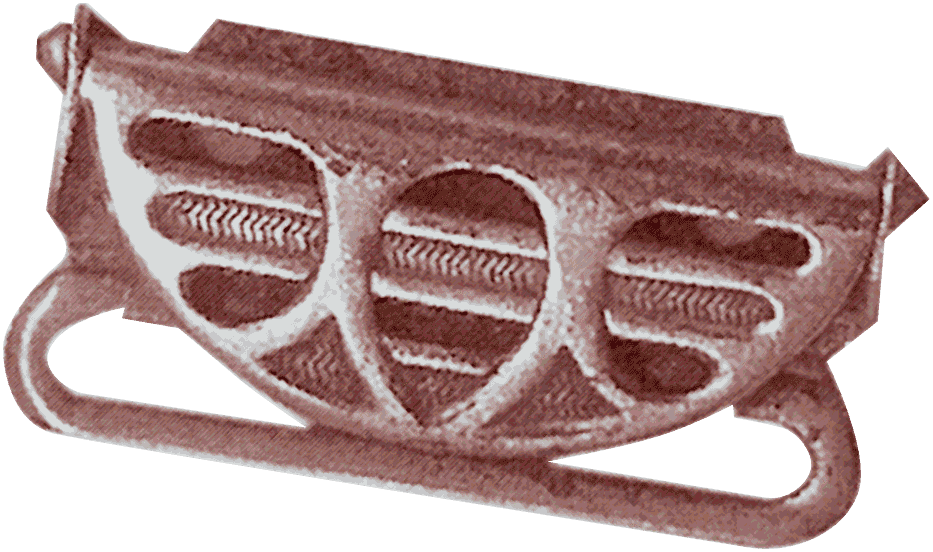

The first trouser brace clip

1953

From this time on, braces could be attached to trousers in other ways. Production began on high-performance machines and was continuously improved through in-house design.

Electroplating and environmental protection

1960

Among other things, special emphasis was placed on a fully automatic pass-through system in electroplating. In addition to the new finishing methods, pioneering work was carried out in the environmental and health protection spheres through detoxification techniques and automatic exhaust air neutralisation.

Relocation for expansion

1980

Move to the current location in Lüdenscheid and expansion of the product range to include technical items made of wire, sheet metal and plastic for the electrical, automotive, and computer industries.

Focus in finishing

1990

Expansion of the electroplating shop and the addition of various filter and neutralisation systems.

DIN EN ISO 9001

2007

Certification according to DIN EN ISO 9001.

Test room for analyses

2018

Setup of test room for bath analysis and layer determination.

New product categories

2020

Production of the first fittings for writing utensils.

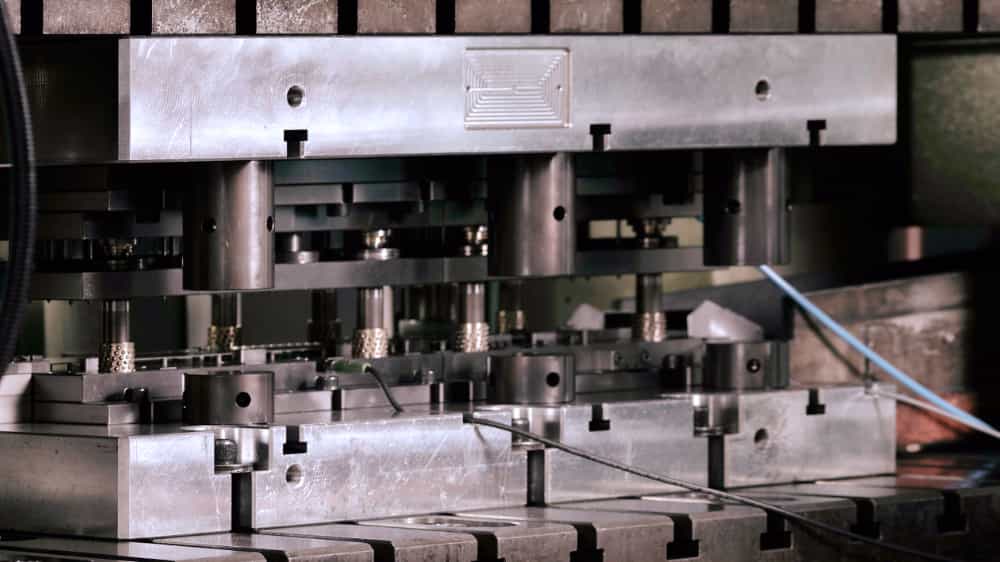

New Haulick

2022

Expanded capacity in the stamping shop with Haulick automatic stamping press (630 KN).

Photovoltaics

2023

Installation and commissioning of a PV system.